Pressure Monitor Systems

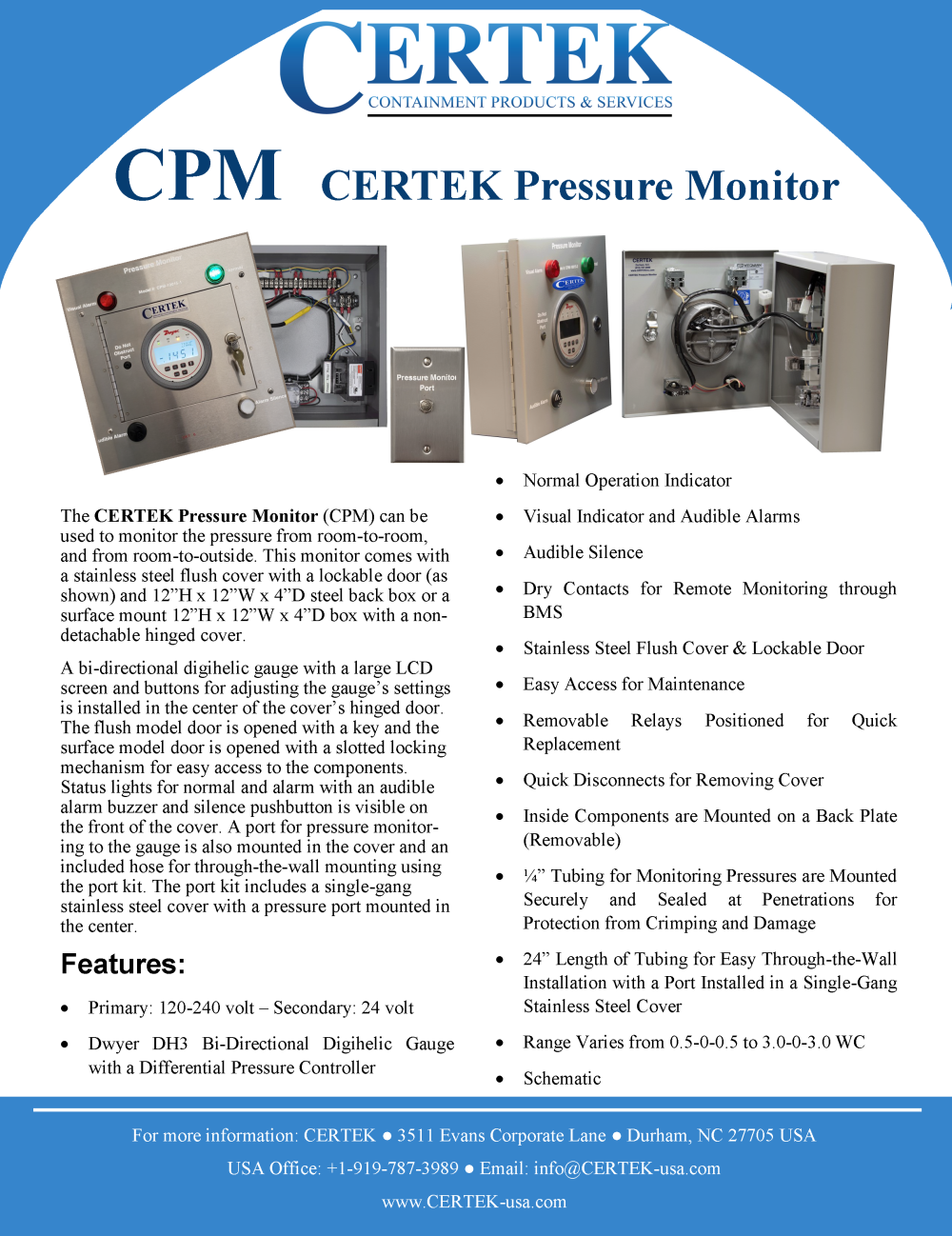

CERTEK Pressure Monitor (CPM Flush and Surface)

Product Description:

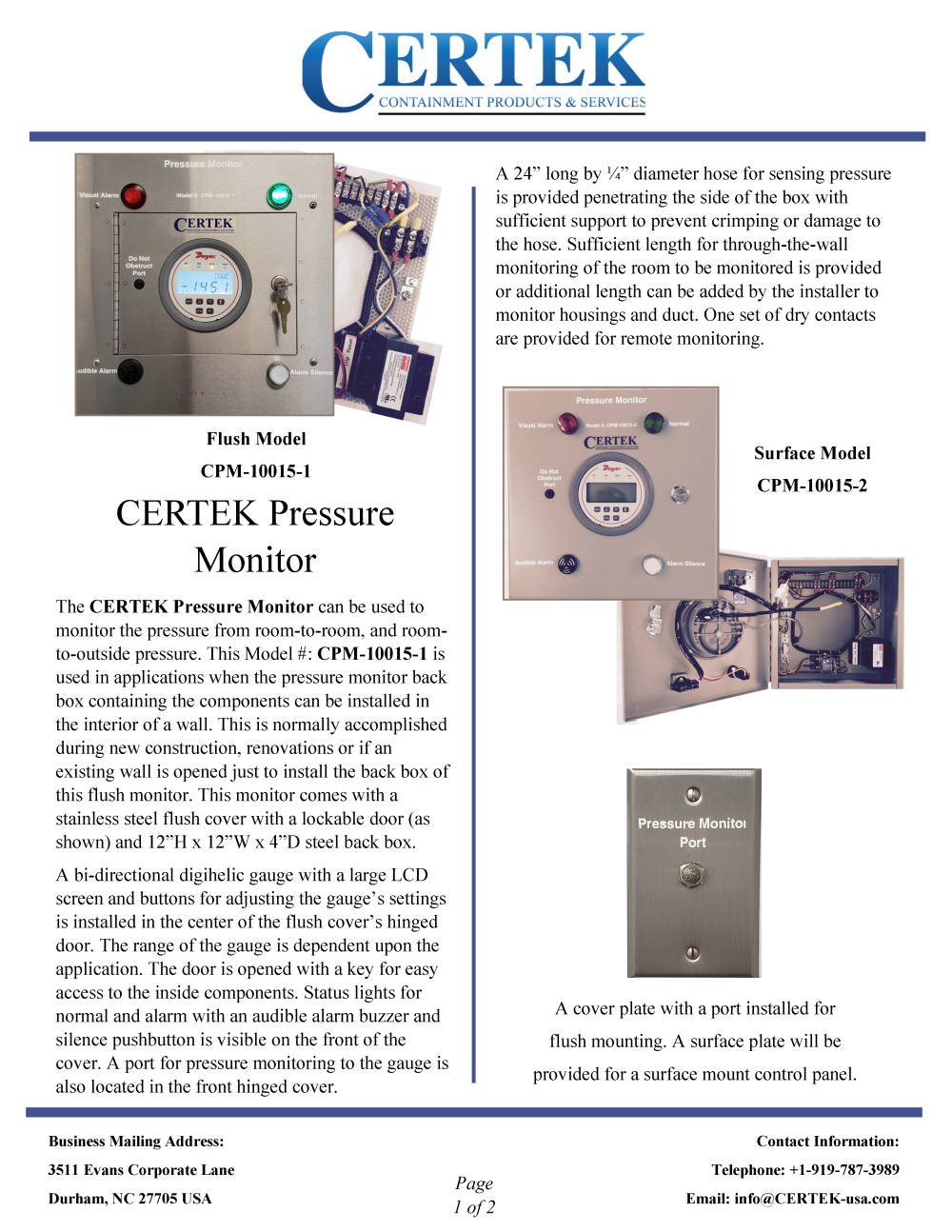

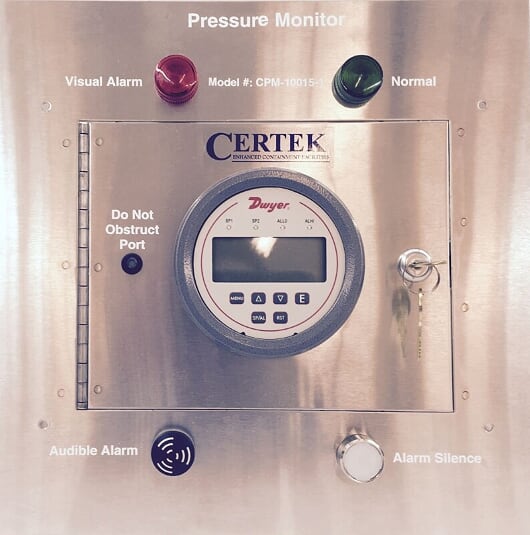

The CERTEK Pressure Monitor (CPM) can be used to monitor the pressure from room-to-room, within filter housings, and within duct. This Model #: CPM-10015-1 (Flush) is used in applications when the pressure monitor back box containing the components can be installed in the interior of a wall. This is normally accomplished during new construction, renovations, or if an existing wall is opened just to install the back box of this flush monitor. This monitor comes with a stainless steel flush cover with a lockable door and a 12”H x 12”W x 4”D steel back box. This Model #: CPM-10015-2 (Surface) is used in surface mounted applications when the pressure monitor back box cannot be installed in the interior of a wall. This is normally accomplished during renovations or in retrofit scenarios. This monitor comes with a hinged non-detachable cover from the 12”H x 12”W x 4”D surface box. The surface box with cover is made of steel with a baked enamel gray coating.

Flush - A bi-directional digihelic gauge with a large digital screen and buttons for adjusting the gauge’s settings is installed in the center of the flush cover’s hinged door. The range of the gauge is dependent upon the application. The door is opened with a key for easy access to the inside components.

Surface - A bi-directional digihelic gauge with a large digital screen and buttons for adjusting the gauge’s settings is installed in the center of the surface box’s hinged cover. The range of the gauge is dependent upon the application. The door is opened by a slotted keyless closer for easy access to the inside components.

Status lights for normal and alarm with an audible alarm buzzer and silence pushbutton is visible on the front of the cover. A port for pressure monitoring to the gauge is also located in the front hinged cover. A 24” length by ¼” diameter hose for sensing pressure is provided penetrating the side of the box with sufficient support to prevent crimping or damage to the hose. Sufficient length for through-the-wall monitoring of the room to be monitored is provided, or additional length can be added by the installer to monitor housings and duct. One set of dry contacts are provided for remote monitoring.

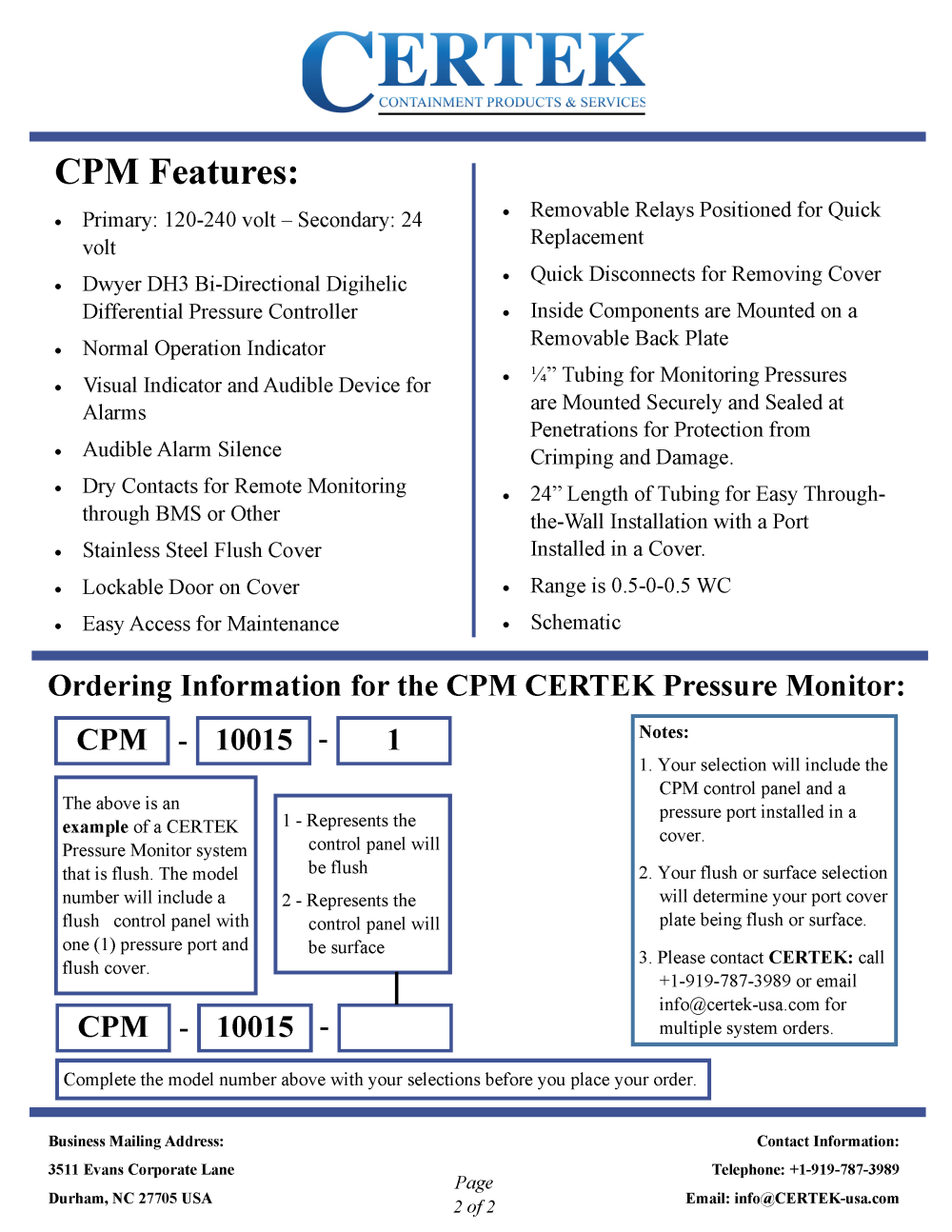

Features:

- Primary: 120 (optional 220 or 240) volt – Secondary: 24 volt

- Dwyer DH3 Bi-Directional Digihelic Differential Pressure Controller

- Normal Operation Indicator

- Power Trip Reset on Transformer

- Visual and Audible Alarm for Monitored Pressure

- Audible Alarm Silence

- Dry Contacts for Remote Monitoring through BMS

- Flush - Stainless Steel Flush Cover

- Flush - Lockable Door on Cover

- Surface - Box and Non-Detachable Cover are made of Steel and Painted for Surface Installations

- Surface - Slotted and Keyless Cover Closer

- Easy Access for Maintenance or Repairs

- Removable Relays Positioned for Quick Replacement

- Quick Disconnects for Removing Cover

- Inside Components are Mounted on a Removable Back Plate

- ¼” Tubing for Monitoring Pressures are Mounted Securely and Sealed at Penetrations for Protection from Crimping and Damage.

- 24” Length of Tubing for Easy Through-the Wall Installation

- Schematic

Model #: CPM-10015-1 (Flush) |

Model #: CPM-10015-2 (Surface) |

CERTEK Pressure Monitor Compact-Flush (CPM-C-F)

Product Description:

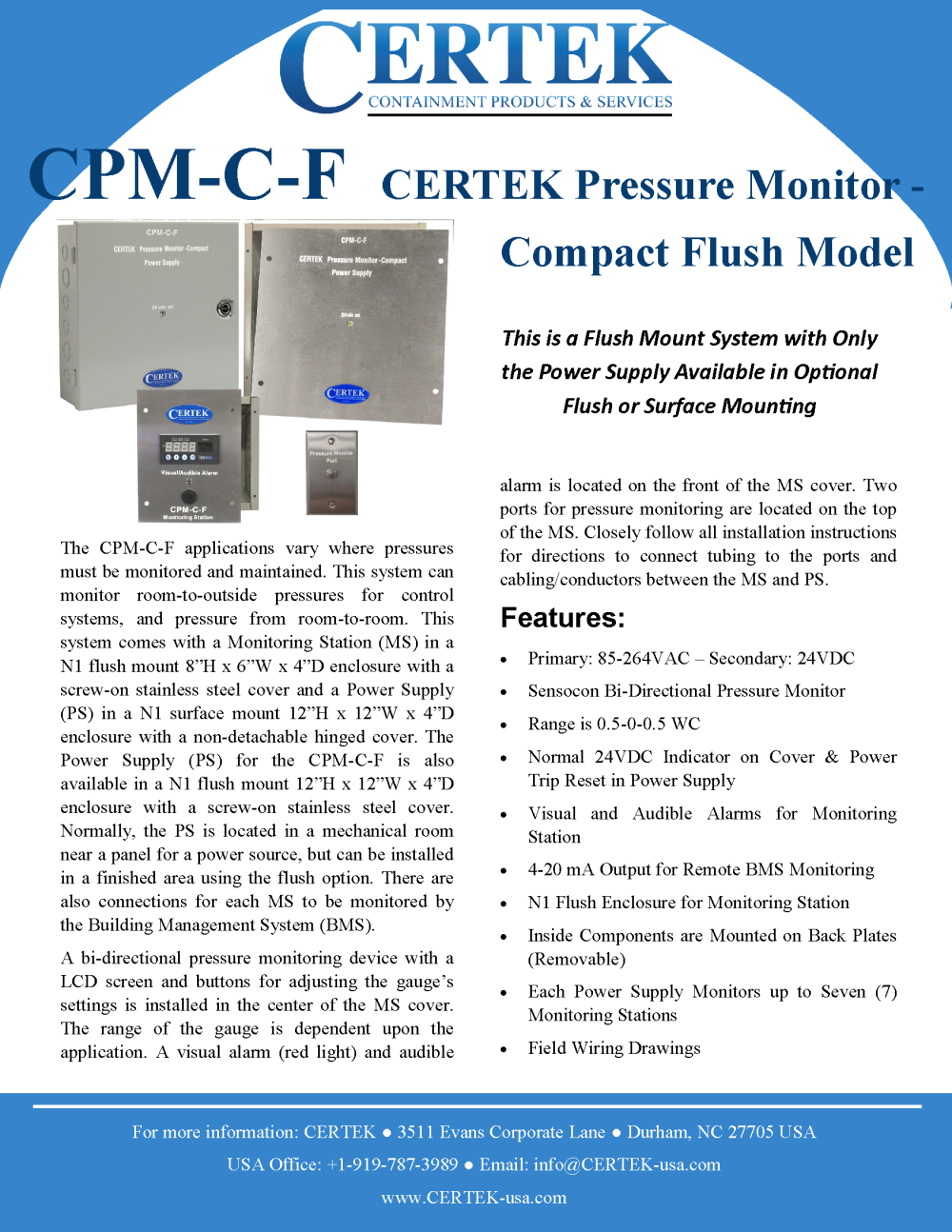

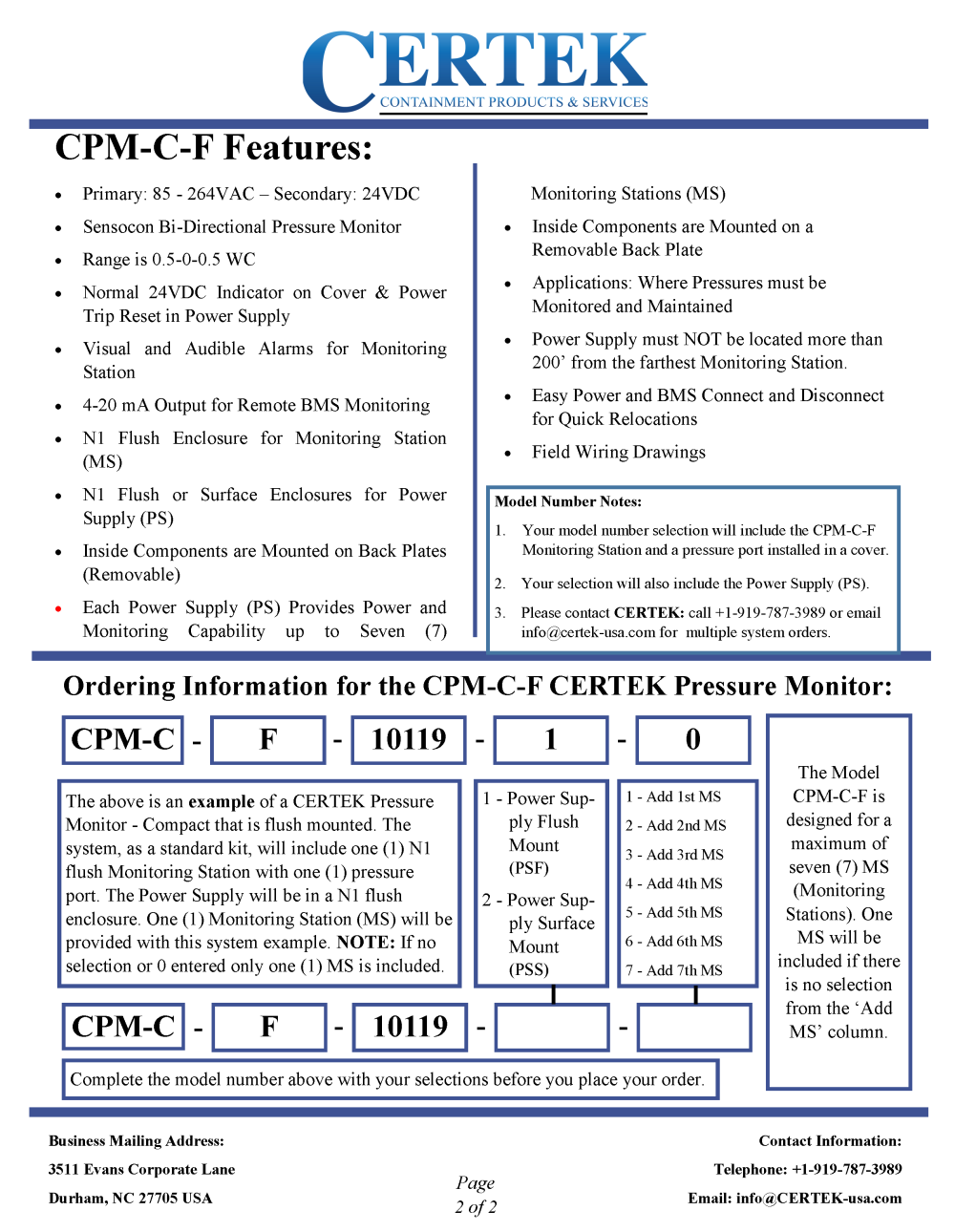

The CPM-C-F applications vary where pressures must be monitored and maintained. This system can monitor room-to-outside pressures for control systems, pressure from room-to-room, within filter housings and within duct. This system comes with a Monitoring Station (MS) in a N1 flush mount 8”H x 6”W x 4”D enclosure with a screw-on stainless steel cover and a Power Supply (PS) in a N1 surface mount 12”H x 12”W x 4”D enclosure with a non-detachable hinged cover. The Power Supply (PS) for the CPM-C-F is also available in a N1 flush mount 12”H x 12”W x 4”D enclosure with a screw-on stainless steel cover. Normally, the PS is located in a mechanical room near a panel for a power source, but can be installed in a finished area using the flush option. There are also connections for each MS to be monitored by the Building Management System (BMS).

A bi-directional pressure monitoring device with a LCD screen and buttons for adjusting the gauge’s settings is installed in the center of the MS cover. The range of the gauge is dependent upon the application. A visual alarm (red light) and audible alarm (piezo buzzer) is located on the front of the MS cover. Two ports for pressure monitoring are located on the top of the MS. Closely follow all installation instructions for directions to connect tubing to the ports and cabling/conductors between the MS and PS.

Features:

- Primary: 85 - 264VAC - Secondary: 24VDC

- Sensocon Bi-Directional Pressure Monitor

- Range is 0.5-0-0.5 WC

- Normal 24VDC Indicator on Cover & Power Trip Reset in Power Supply (PS)

- Visual and Audible Alarms for Monitoring Station (MS)

- 4-20ma Output for Remote BMS Monitoring

- N1 Flush Enclosure for Monitoring Station (MS)

- N1 Flush or Surface Enclosures for Power Supply (PS)

- Each Power Supply (PS) Provides Power and Monitoring Capability up to Seven (7) Monitoring Stations (MS)

- Inside Components are Mounted on a Removable Back Plate

- Applications: Where Pressures must be Monitored and Maintained

- 24VDC Tested up to 250’ with a .01% drop for One Monitoring Station (MS)

- Easy Power and BMS Connect and Disconnect for Quick Relocations

- Drawing/Installation Instructions

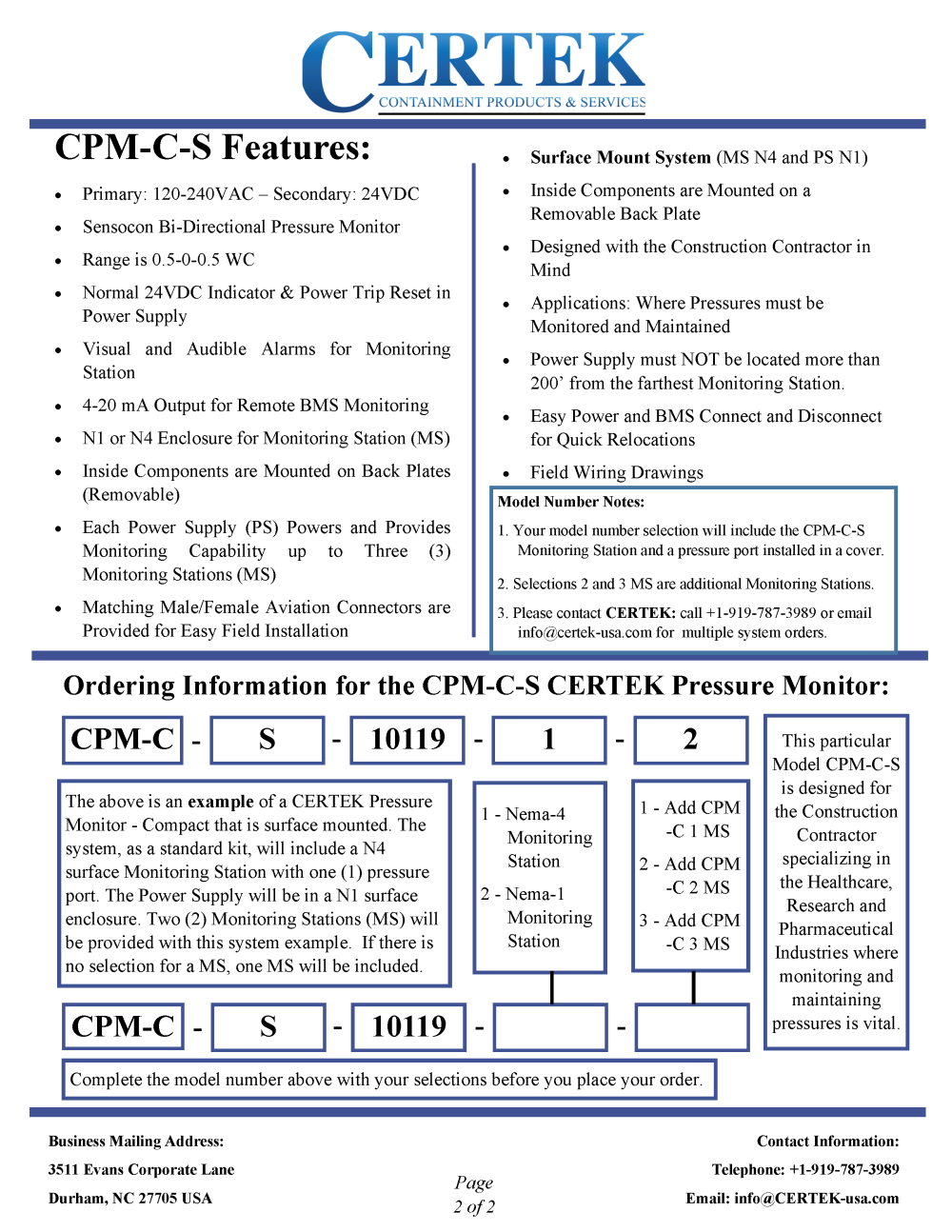

CERTEK Pressure Monitor Compact-Surface (CPM-C-S)

Product Description:

The CPM-C-S is robust and fits any construction application where pressures must be monitored and maintained. It can also be used to monitor the pressure from room-to-room, within filter housings and within duct. This system comes with a surface mount Monitoring Station (MS) in a N1 or N4 8”H x 6”W x 4”D enclosure and the Power Supply (PS) in a surface mount 12”H x 12”W x 4”D enclosure with a non-detachable hinged cover. The MS is to be mounted in or near the construction area and a connecting cable (supplied by the customer) is run between the MS and the PS located in another area. Normally, the PS is located in a mechanical room near a panel for a power source. There are also connections for the MS to be monitored by the Building Management System (BMS).

A bi-directional pressure monitoring device with a LCD screen and buttons for adjusting the gauge’s settings is installed in the center of the MS cover’s hinged door. The range of the gauge is dependent upon the application. A visual alarm (red light) and audible alarm (piezo buzzer) is located on the front of the MS cover. Two ports for pressure monitoring are located on the top of the MS. Closely follow all installation instructions for directions to connect vinyl tubing to the ports and cabling/conductors between the aviation connectors of the MS and PS.

Features:

- Primary: 120-240VAC - Secondary: 24VDC

- Sensocon Bi-Directional Pressure Monitor

- Range is 0.5-0-0.5 WC

- Normal 24VDC Indicator & Power Trip Reset in Power Supply

- Visual and Audible Alarms for Monitoring Station

- 4-20ma Output for Remote BMS Monitoring

- N1 or N4 Enclosure for Monitoring Station (MS)

- Inside Components are Mounted on Back Plates (Removable)

- Each Power Supply (PS) Powers and Provides Monitoring Capability up to Three (3) Monitoring Stations (MS)

- Matching Male/Female Aviation Connectors are Provided for Easy Field Installation

- Surface Mount System (MS N4 and PS N1)

- Inside Components are Mounted on a Removable Back Plate

- Designed with the Construction Contractor in Mind

- Applications: Where Pressures must be Monitored and Maintained

- 24VDC Tested up to 250’ with a .01% drop for One Monitoring Station (MS)

- Easy Power and BMS Connect and Disconnect for Quick Relocations

- Drawing/Installation Instructions